Difference between Genuine Leather and Imitation Leather

Oct 27, 2022

Dermis

Genuine leather refers to all kinds of original skins stripped from animals, such as cow skin, pig skin, sheep skin, crocodile skin, etc. The head skin is directly processed from the raw skin of various animals, or the thick skin of cattle, pigs, horses and other animals is cut into upper and lower layers after depilation, and the upper part with tight fibrous tissue is processed into various head skin. For example, the most common cowhide in life is divided into the first layer and the second layer. The second layer of leather, also known as film covered leather, is composed of the second layer of animal skin or leftover material broken and PU resin. The second layer of leather is generally weaker than the first layer of cow leather in toughness, feel and wear resistance. Although it has the quality of leather, it has no real leather.

Faux Leather

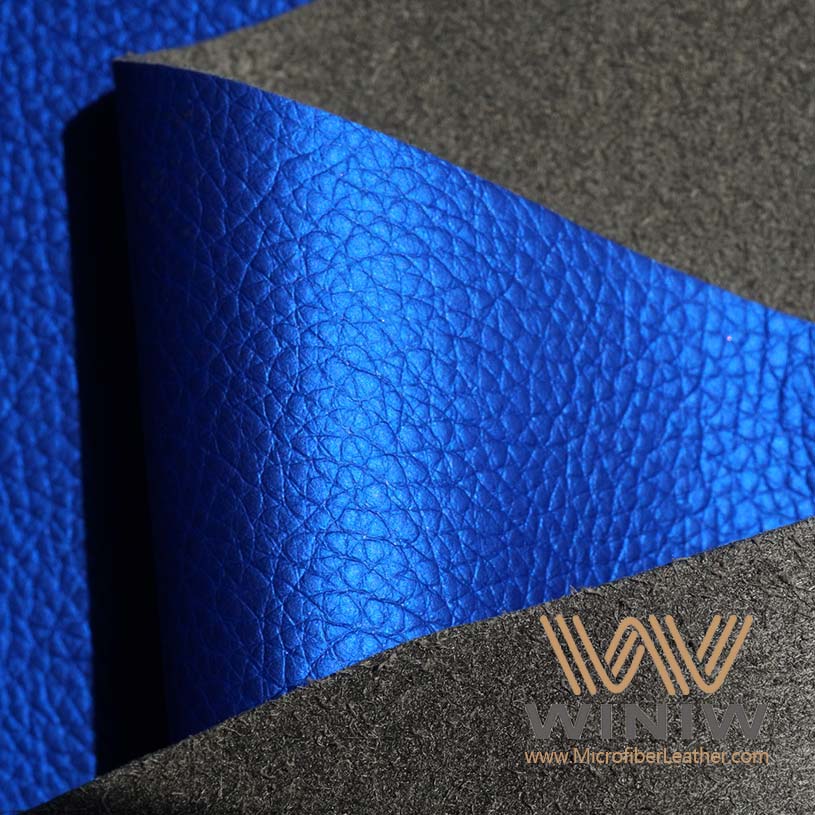

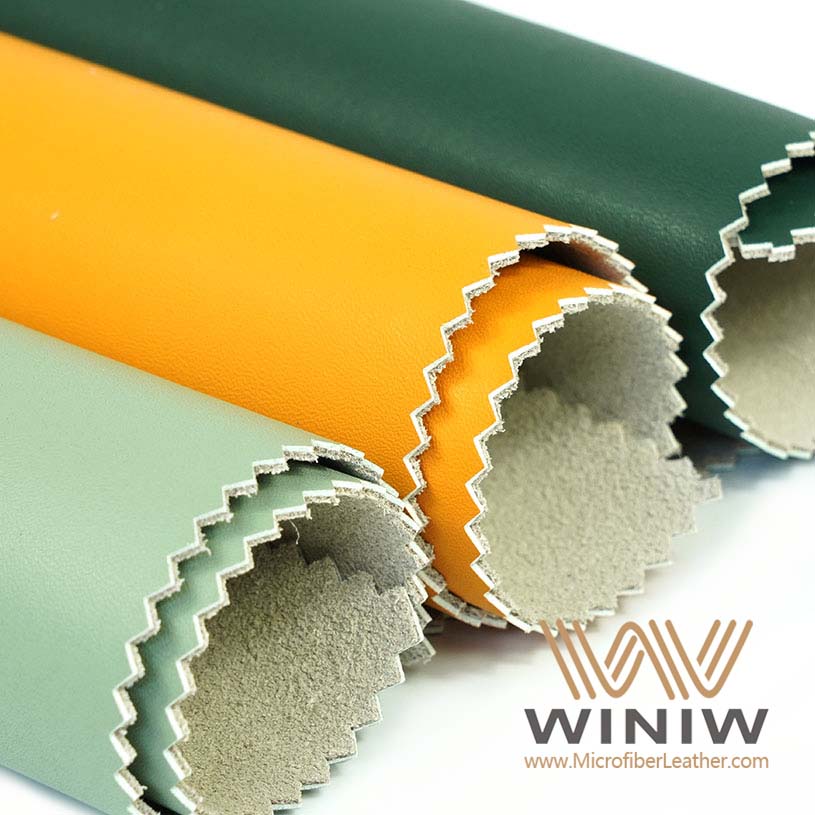

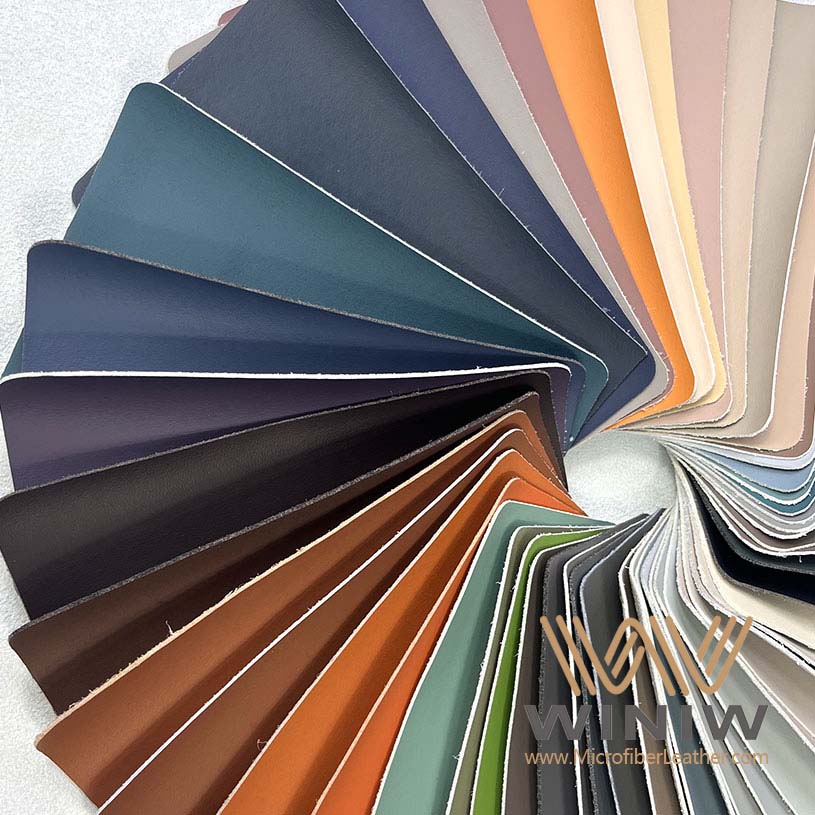

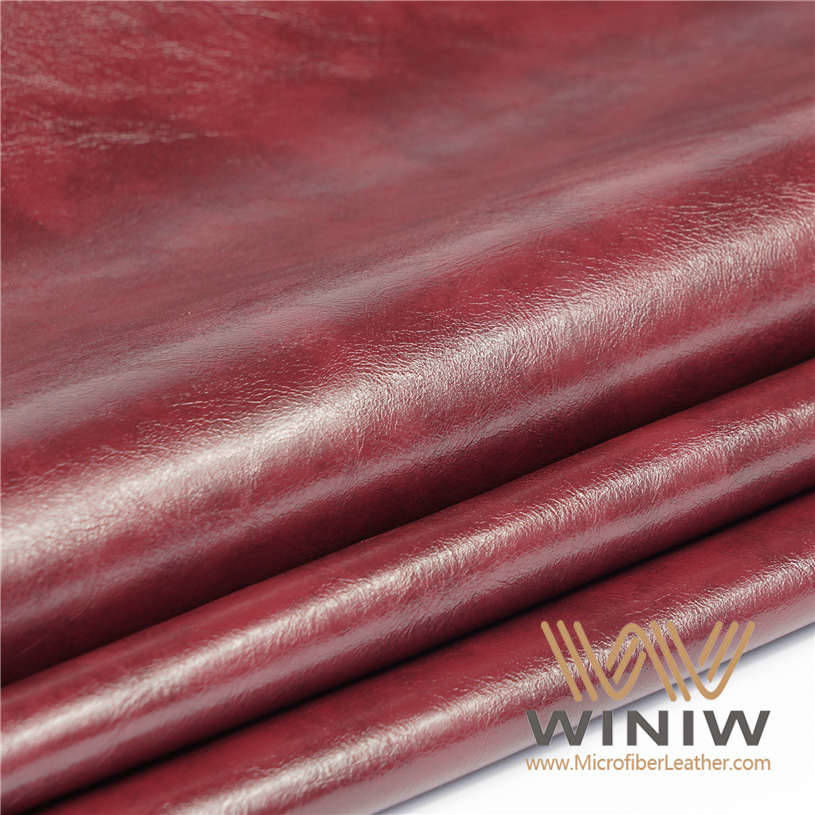

Faux leather refers to artificial leather, or artificial leather. Common products include PU, PVC and microfiber. Sometimes some businesses like to add the word "leather" after these names when writing ingredients on the label to confuse the public. For example, PU leather and microfiber leather, but they are not genuine leather. Ultrafiber leather, ordinary PU and PVC are products of artificial synthetic leather at different development stages and different technical levels. The surface layer of microfiber leather and ordinary PU is polyurethane resin, Ordinary PU is made of knitted fabric, woven fabric or non-woven fabric as the base fabric, and then coated with polyurethane resin. The microfiber skin is made of superfine fiber non-woven fabric with three-dimensional structure as the base cloth, coated with high-performance polyurethane resin. The super fiber leather is generally superior to other artificial leather in the sense of imitation leather and practical performance.

In general, the price of leather products is higher than that of imitation leather products, especially the first layer of leather, which tends to give people the feeling that leather is better than artificial leather. In fact, this is not the case. In many cases, the price of leather is due to the scarcity of its sources and the cumbersome treatment process of animal skin. However, with the development of technology, many excellent properties of artificial leather can not be achieved by leather, such as WINIW microfiber leather, because it is firm and wear-resistant, Low loss, non killing, highly respected in Europe and the United States, has gradually become the preferred material to replace leather.